Self Adhesive EPE Foam

10 INR/Metric Ton

Product Details:

- Material EPE Foam

- Texture Smooth

- Product Style Self Adhesive

- Characteristics Lightweight, Flexible, Shock Absorbent, Moisture Resistant

- Application Packaging, Cushioning, Insulation, Soundproofing

- Thickness 2 mm to 10 mm (customizable)

- Hardness Medium

- Click to View more

X

Self Adhesive EPE Foam Price And Quantity

- 5 Metric Ton

- 10 INR/Metric Ton

Self Adhesive EPE Foam Product Specifications

- EPE Foam

- Rolls or Sheets packed in Poly Bags

- Rolls, Sheets, Cut Pieces

- Plain

- White

- Lightweight, Flexible, Shock Absorbent, Moisture Resistant

- Rectangular, Custom Shapes available

- 2 mm to 10 mm (customizable)

- Smooth

- Medium

- Packaging, Cushioning, Insulation, Soundproofing

- Yes

- Length up to 100 m, width up to 1.5 m (customizable)

- Self Adhesive

Self Adhesive EPE Foam Trade Information

- 1 Metric Ton Per Day

- 1 Days

- Maharashtra

Product Description

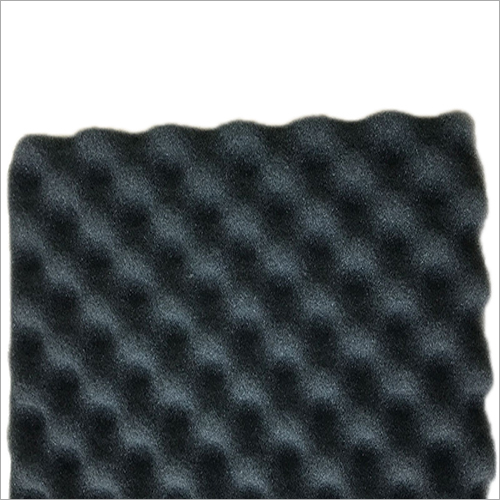

Fostered with immense industrial expertise, we provide Self Adhesive EPE Foam, which is basically a molded semi-rigid, non-cross linked and closed-cell type of polyethylene foam. Self Adhesive EPE Foam finds usage in cushioning applications, and impact absorption applications including packaging. Further, it is checked on various parameters in order to ensure its long term usage.

Superior Adhesion and Flexibility

This EPE foam utilizes pressure sensitive adhesive for quick and secure attachment to a range of surfaces. Its lightweight and flexible nature allows it to conform perfectly to custom shapes and contours, making it ideal for insulation, packaging, and shock absorption. The matte finish and odorless composition add value in sensitive applications.

High Performance and Environmental Safety

Designed for demanding conditions, the foam is highly water resistant and can withstand temperatures from -40C to +70C. It features moderate UV resistance and can be supplied with flame retardant properties when required. Fully recyclable and compliant with RoHS standards, it supports eco-friendly practices without compromising durability.

Versatile Applications and Customization

Available in multiple thickness options and customizable sizes up to 100 meters in length and 1.5 meters in width, our EPE foam is suitable for packaging, soundproofing, and insulation needs. Choose from rolls, sheets, or tailored piecesincluding rectangular and other custom shapesfor a precise fit in your project.

FAQs of Self Adhesive EPE Foam:

Q: How is self-adhesive EPE foam installed?

A: Self-adhesive EPE foam is applied by peeling off the protective backing and pressing the foam firmly onto the desired clean surface. The pressure sensitive adhesive ensures a secure attachment without the need for extra glues or fasteners.Q: What benefits does the high water resistance of EPE foam offer for packaging and insulation?

A: The high water resistance prevents moisture penetration, making it ideal for protecting sensitive goods during shipping and providing effective insulation in humid environments.Q: When is the flame retardant option recommended for EPE foam?

A: Request the flame retardant version when the foam will be used in applications requiring enhanced fire safety, such as industrial packaging, construction, or insulation in buildings.Q: Where can self-adhesive EPE foam be used?

A: It is widely used in packaging, cushioning electronics and fragile items, insulation in buildings and vehicles, as well as soundproofing for studios and offices. Its versatility suits both industrial and commercial spaces.Q: What is the process for customizing the foams thickness, size, or shape?

A: Manufacturers and suppliers offer customization according to your specifications for thickness (2 mm to 10 mm), length, width, and shape. Custom shapes and cut pieces can be requested to fit unique project needs.Q: How does EPE foam contribute to environmental compliance and sustainability?

A: EPE foam is RoHS compliant, CFC free, and 100% recyclable. Its safe composition and recyclability make it an eco-friendly choice for businesses looking to minimize environmental impact.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email